Reliability and safety are found as the most desired characteristics of devices applied in industrial processes. To meet customers’ need, Tapflo offers tailor-made flow systems of the highest quality.

Our mission is to provide technical solutions that guarantee proper functionality and stable operation in every environment.

High Viscosity System (HVS)

The HVS Drum Unloading System is designed for handling highly viscous liquids in industrial as well as hygienic applications. The system is emptying substances transported in barrels...

HVS Quattro

Simplify the unloading of highly viscous liquids with our High Viscosity System Quattro-type (HVS Quattro). It is designed for high-volume applications where multiple drums (typically four) are stored on pallets.

HVS Flexi

Unloading drums containing highly viscous liquids has become more efficient and precise with our High Viscosity System Flexi-type (HVS Flexi). This system simplifies the task, providing automation and effective product-saving features.

SLES Mixing & Dilution Unit

SLES* is an organic chemical compound with excellent cleansing and foaming properties. For this reason it is an ingredient of various detergents, household products, soaps and shampoos.

In-line Blending System

Mixing various ingredients by the recipe of the final product, together with keeping the required proportion...

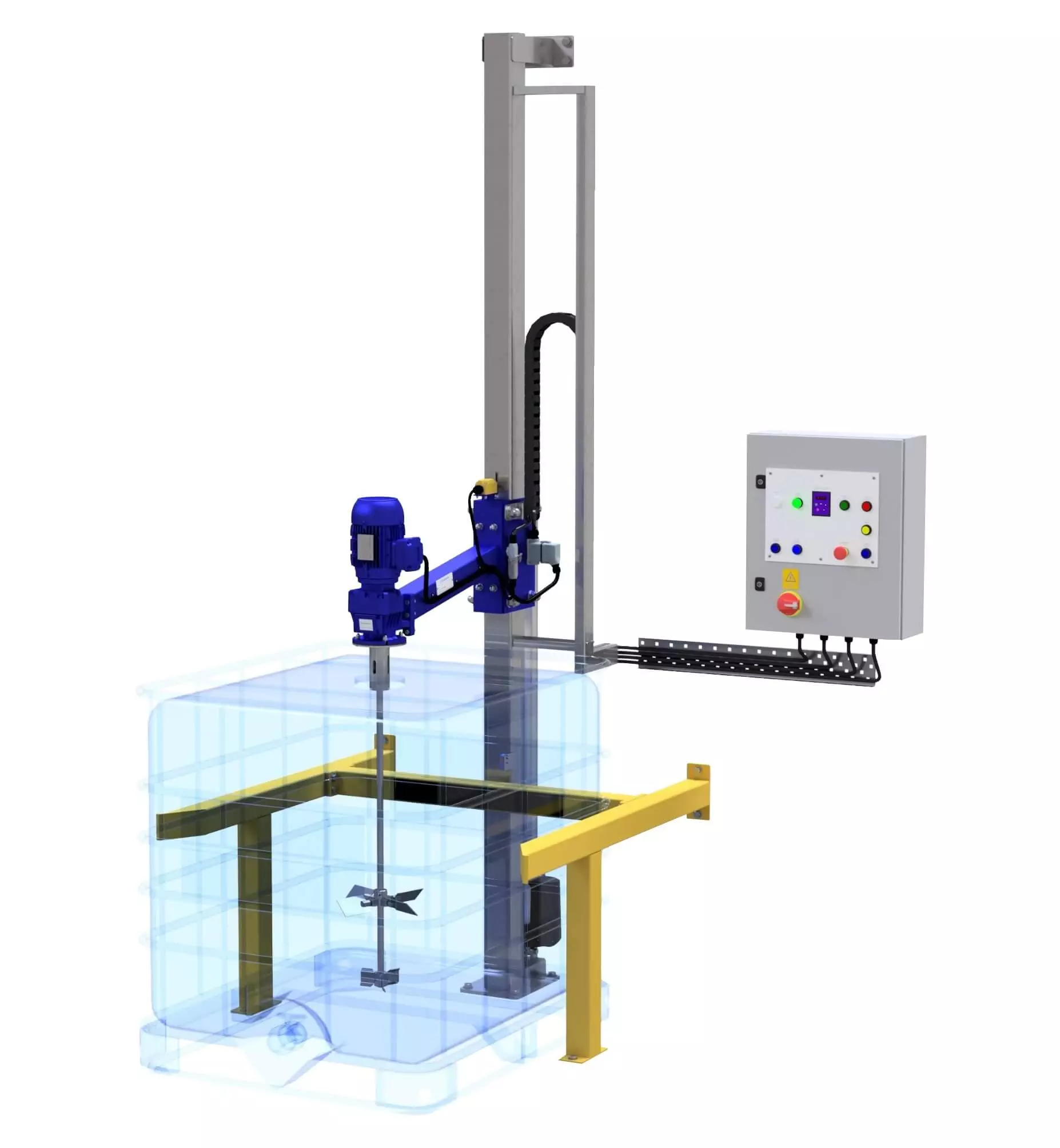

IBC Mixing Station

Save your time and use one, complete solution for mixing various liquid products...

SKID - Customised Process Units

Based on strong experience in design and production, Tapflo offers wide range of compact process pumping systems. We create units that are dedicated to certain applications in certain industrial sectors.

Integrated Solutions

Combining different flow components into one complex unit is an opportunity to suit individual customers’ needs, that are related to: required equipment & functionality, available space, position of connecting flanges, mobility

Tank Units

Tapflo Tank Units are perfect for storing and transferring or dosing liquids in every branch of industry. Various sizes of tanks and robust pumps in multiple executions are available together with additional equipment.

HVS Quattro

Simplify the unloading of highly viscous liquids with our High Viscosity System Quattro-type (HVS Quattro). It is designed for high-volume applications where multiple drums (typically four) are stored on pallets.

HVS Flexi

Unloading drums containing highly viscous liquids has become more efficient and precise with our High Viscosity System Flexi-type (HVS Flexi). This system simplifies the task, providing automation and effective product-saving features.

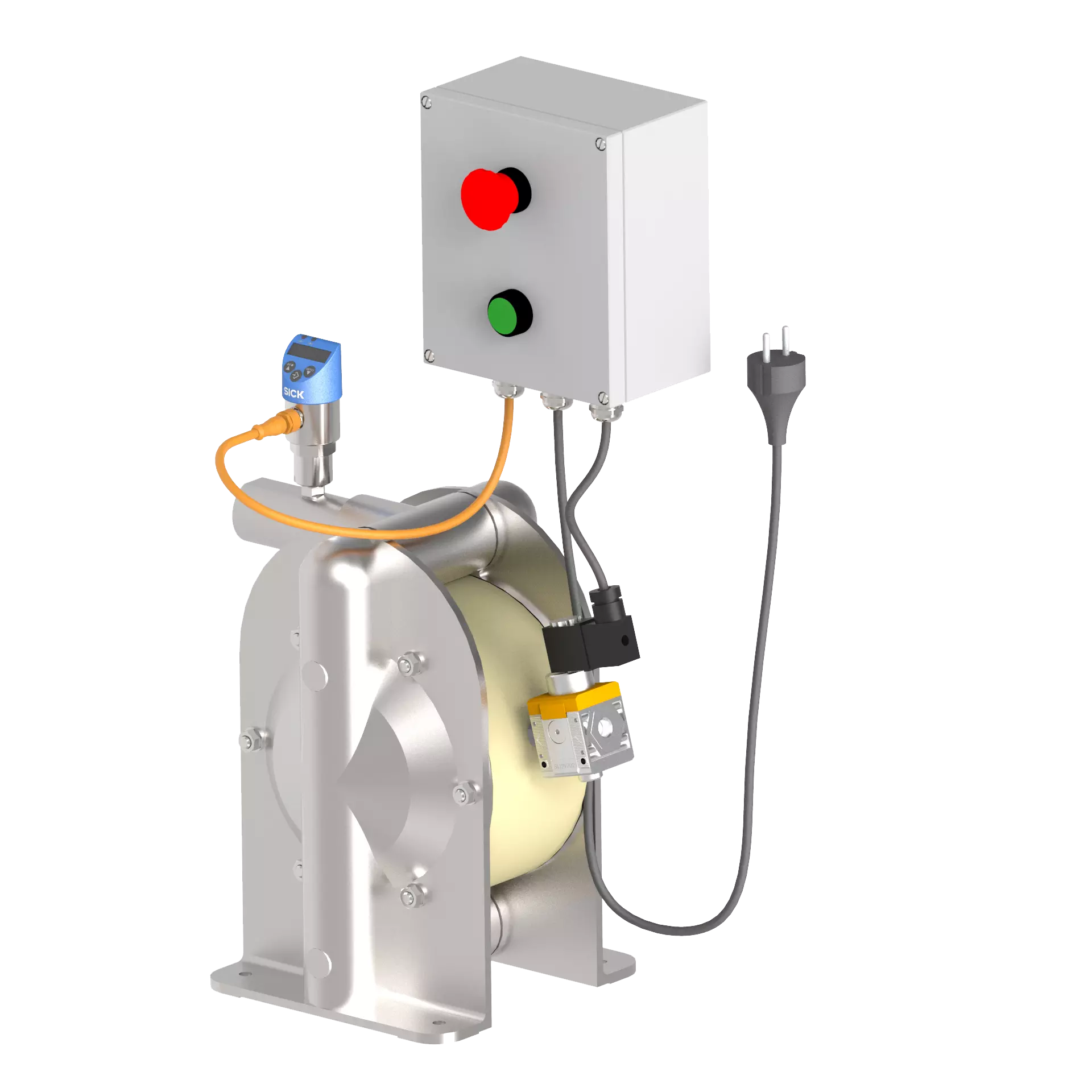

Electronic Batch Controller

Electronic Batch Controller is an automation unit designed to perform a batching process.

Working together with Tapflo diaphragm pumps, it allows transferring almost every liquid.

Automation & Control solutions

Tapflo is proud to announce, that we have broaden our offer with automation & control solutions. By using both pneumatic and electric devices to monitor flow parameters, we are able to ensure safe work of all Tapflo pump units.

Insulating Covers

Sound insulation, thermal insulation or even pump heating within a cover. Now all this is available from Tapflo!