Fast facts

| Pump length: | up to 6 meters |

| Mounting plate: | rectangular, circular or according to customer’s specifications PTFE LIP SEAL or CARTRIDGE SEAL for vapor proof construction or pressurized designs. |

| Materials: | Cast Iron GJL250 or AISI 316. Upon request AISI 304, AISI 904, duplex, superduplex. |

| Bearing bush materials: | bronze, rubber, RULON and PEEK |

| Suction strainer and suction extension on request. | |

Vertical immersible sump pump (ISO 5199 norms) line-shaft with bearing bushes.

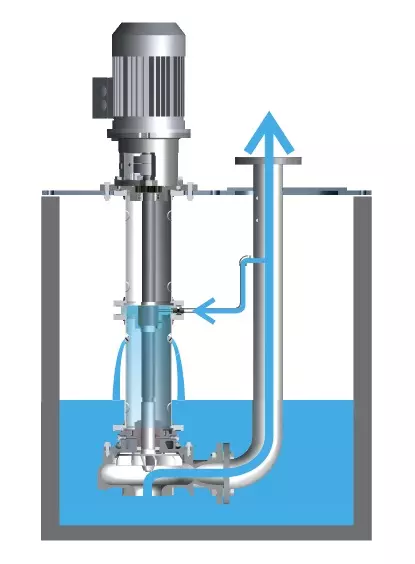

The pump body is immersed into the liquid, whilst the motor is mounted above the plate, keeping it away from the liquid.

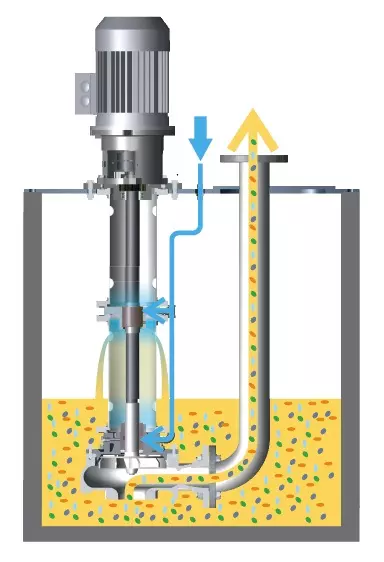

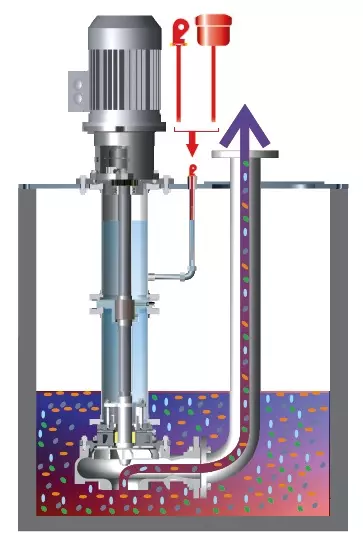

The discharge pipe is separated from the column pipe and the lubrication of the line bearings is normally obtained by means of the same pumped fluid, or from an external lubricating source (such as clear liquid or grease) in abrasive services.

The possibility to customize mounting plate shape and dimensions, discharge flange position and column length, allows designers and end-users to match sump or tank plates or flanges.

FIELDS OF APPLICATION:

Used in all industrial applications, refining, oil and gas production, chemical, pulp & paper and water facilities.

Typical applications include:

drainage sumps, oily water sumps, tank transfer.