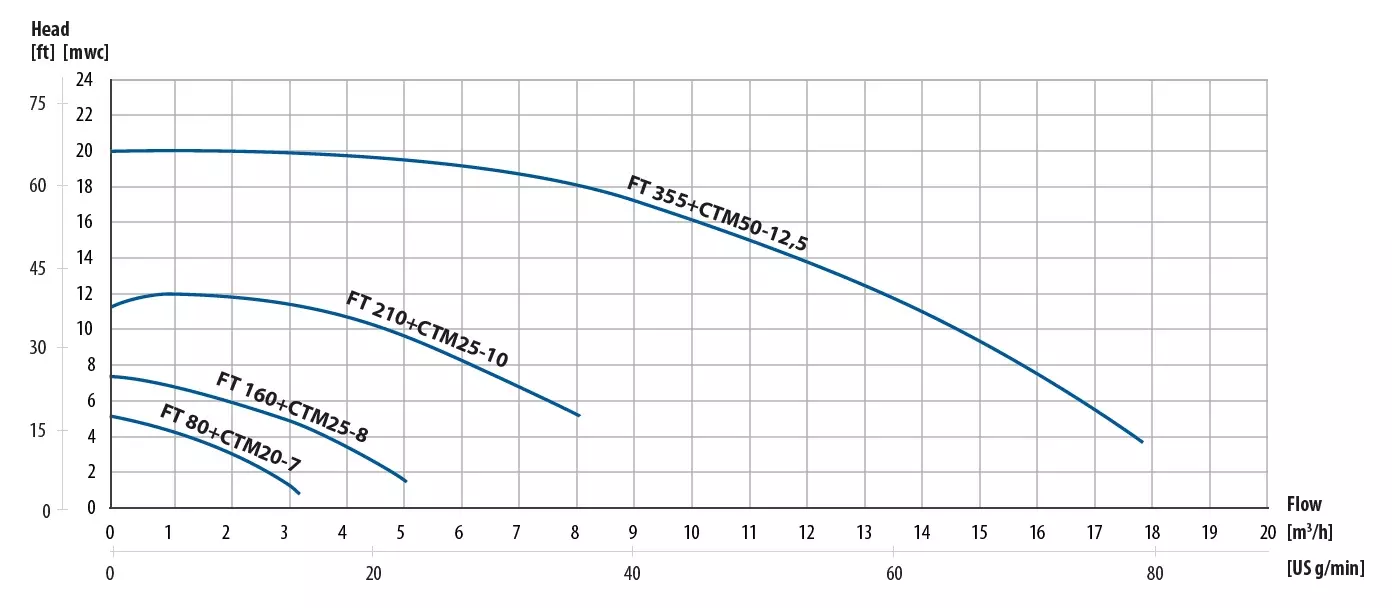

Technical data

| Pump size | FT80 | FT160 | FT210 FTB210 |

FT355 |

| Applicable tank size (L) |

400 | 1200 | 2800 | 6000 |

| Filter capacity (m3/h) |

3,5 | 5,2 | 14 | 18,1 |

| Max head (m) | 5,0 | 7,2 | 11,2 | 20,1 |

| Motor power (kW) | 0,12 | 0,25 | 0,55 | 3,0 |

| Filter housing | PP | |||

| O-rings | EPDM, NBR, FKM | |||

| Temperature range | 0°C - 70°C | |||

CREATING A SAFE PROCESS

FT Filters are developed to work in various applications, where process quality often relies on the bath filtration. As there are many hazardous substances used, it is of paramount importance to ensure these chemicals are handled in a safe way.

Tapflo is here to provide you reliable solutions that increase both quality and safety of your filtration processes.

FEATURES & BENEFITS

Simple and smart design

New FT Filters were designed to reduce the number of parts to minimum. Filters are easy to maintain and service and the inserts are easy to replace.

Changeable inserts

Thanks to the universal body design, the FT Filter units can be equipped with various filtering inserts. It allows the filters to work with surface treatment baths, oil absorbing systems and precious metals treatment systems.

Wide range of filtering volume

Filtering volumes which exact the needs of various applications. Suitable for tanks capacity form 200 l (for FT80) to 6000 l (for FT355).

Solid construction

FT Filters are made to work in a tough industrial environment; its robust design provides a safe and reliable daily work environment, both with acids and alkali. Our FT Filters are ready to resist hard conditions all over the world.

Typical APPLICATIONS

- Surface treatment

- Precious metal plating

- Chemical industry

- Paints and varnishes

- Water treatment