Typical applications

| Food & Beverage CTX H |

| Transfer of various ingredients and products like edible oil, flavor, alcohol and juice. There are also many auxiliary applications like the transfer of cleaning liquids and water. |

| Dairy CTX H |

| Transfer milk, yogurt, cream, curds and whey, skimmed milk, butter, cottage cheese, melted cheese, ice cream. |

| Chemical & Pharma CTX H & CTX I |

| Transport of chemicals and ready products from storage tanks, containers, and baths, for example in degreasing. Transfer of soap, SLES, solvents, creams, oils, alcohol, gels. Handling of waste products. |

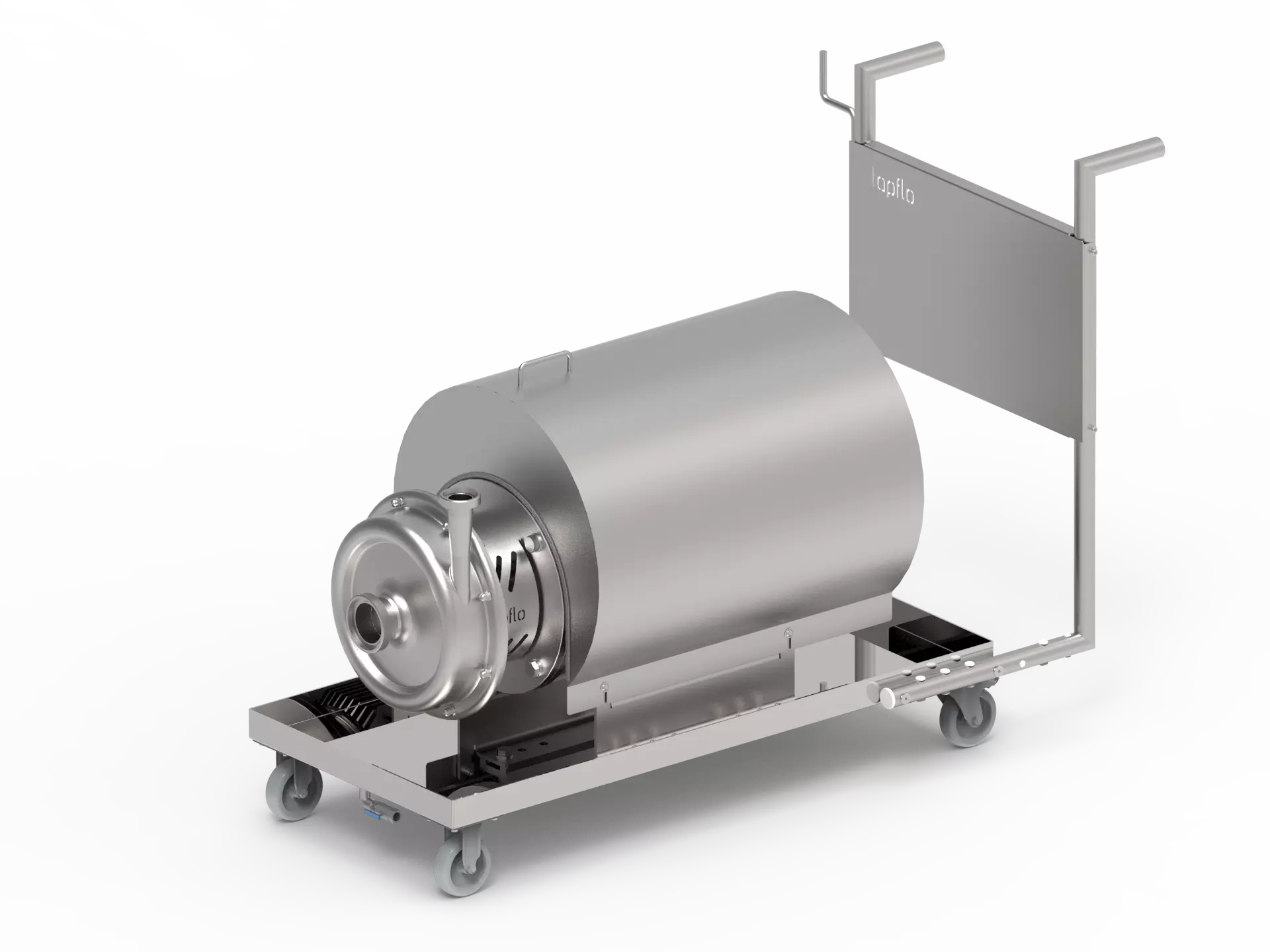

The premium pump series from Tapflo with superior performance

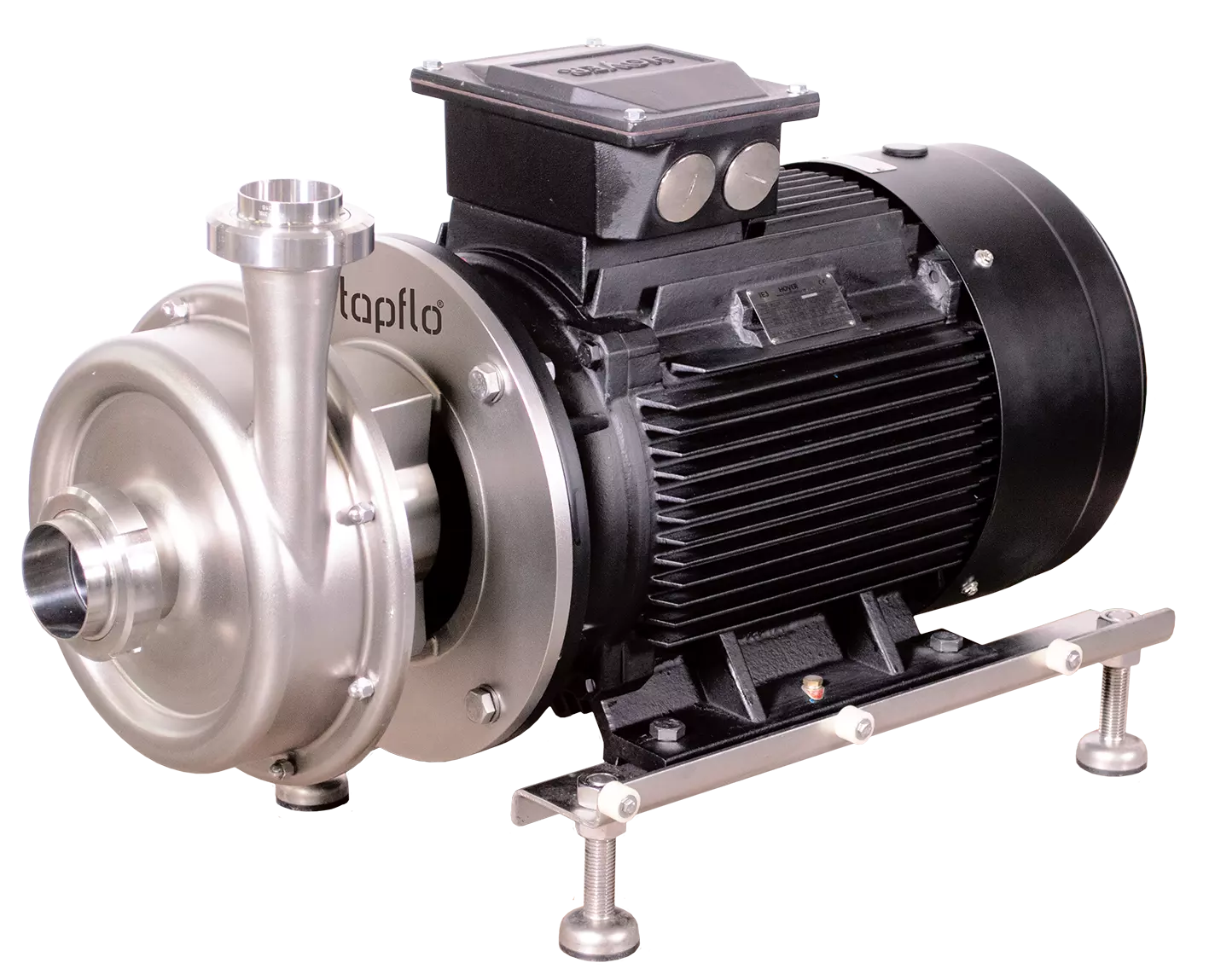

Thanks to the robust construction and a compact and reliable design, centrifugal high performance pumps CTX assure long term failure-free operation thus short downtimes. CTX pumps are available in Hygienic (CTX H) and Industrial execution (CTX I).

Fast facts

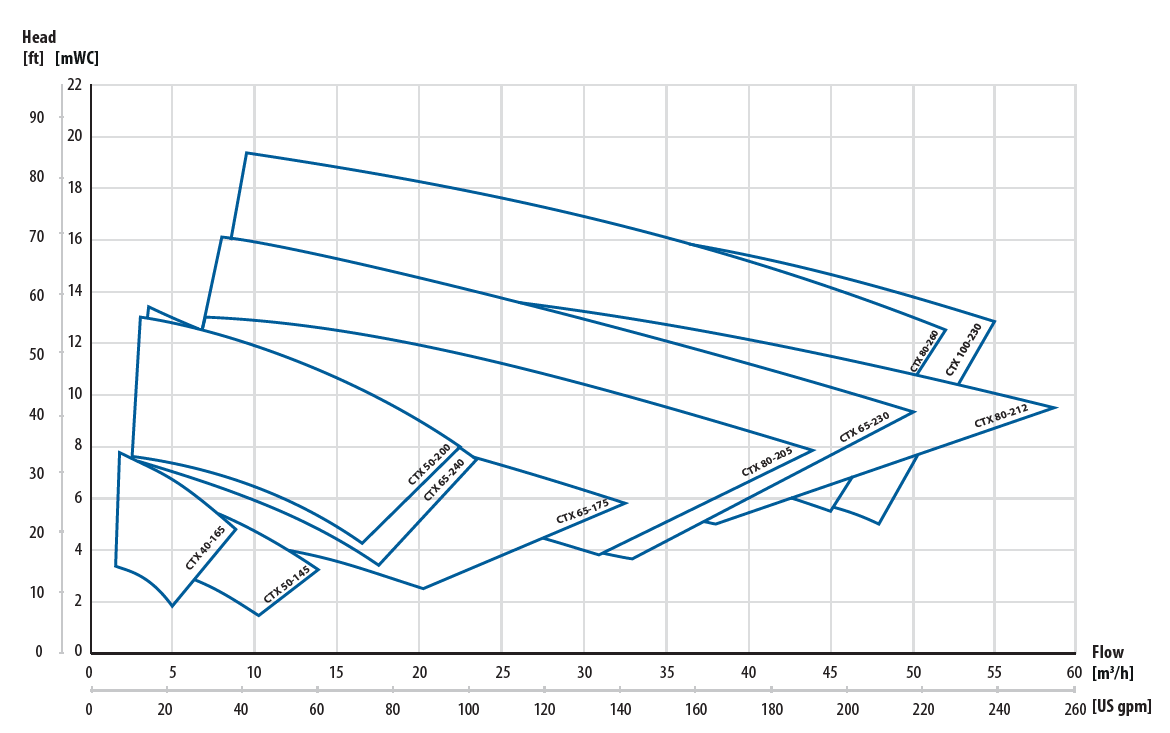

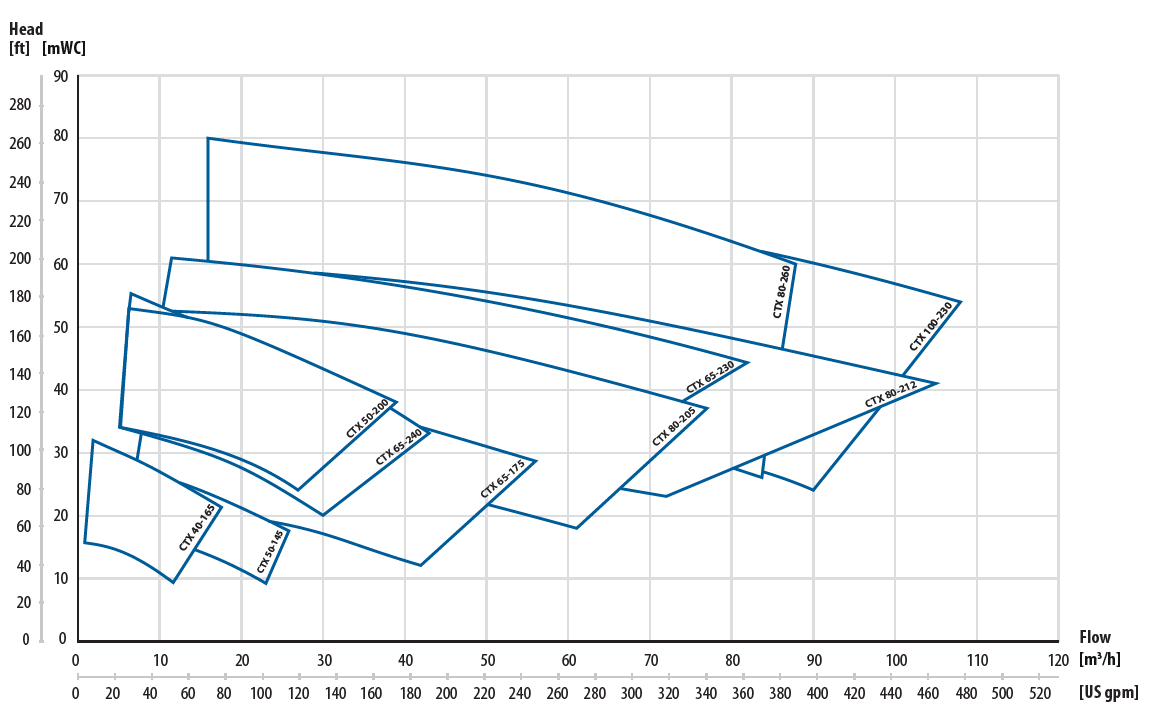

- Capacity: 2.5 - 125 m3/h

- Max head: 88 m

- Liquid temperature range: -10 °C ... + 120 °C

- Ambient terperature range: -20 °C ... + 40 °C

Features & benefits

- Designed for the applications requiring high efficiency

- Available in Hygienic & Industrial execution

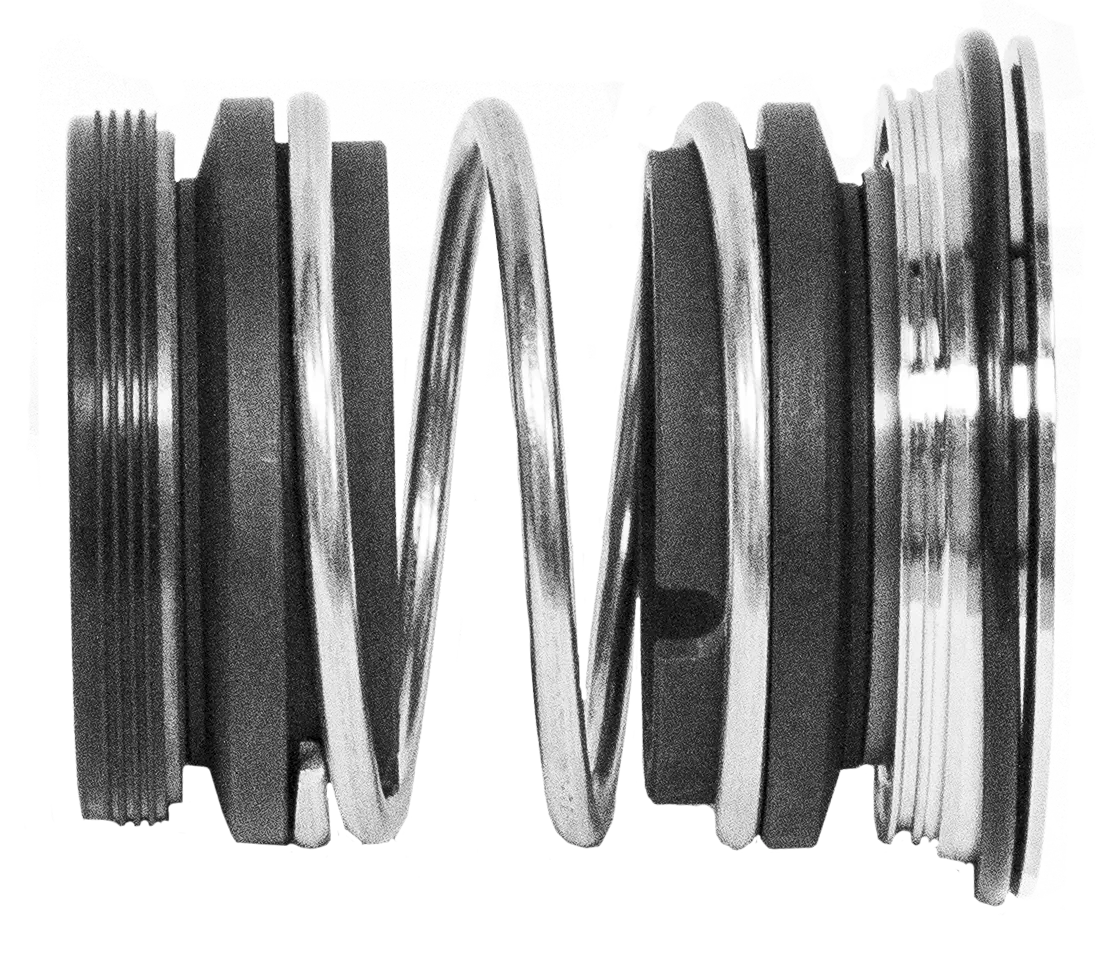

- Single or double mechanical seal

- Low noise & low vibration

- The Impeller can be adjusted (trimmed)to work with specific parameters

- Robust construction and easy maintenance thus less downtime

- Modular design concept

- Low NPSHr