Fast facts

| Pump length: | up to 1,8 meters. Can be extended by means of a suction extension allowing the pump to operate with a liquid level under the impeller level |

| Mounting plate: | rectangular, circular or according to customer’s specifications PTFE LIP SEAL for vapor proof construction. |

| Materials: | Cast Iron GJL250 or AISI 316. |

| Bearing bush materials: | bronze, rubber, RULON and PEEK Upon request CA6NM (400HB hardness), AISI 304, AISI 904, duplex, superduplex, CA6NM (400HB hardness). |

| Suction strainer and suction extension on request. | |

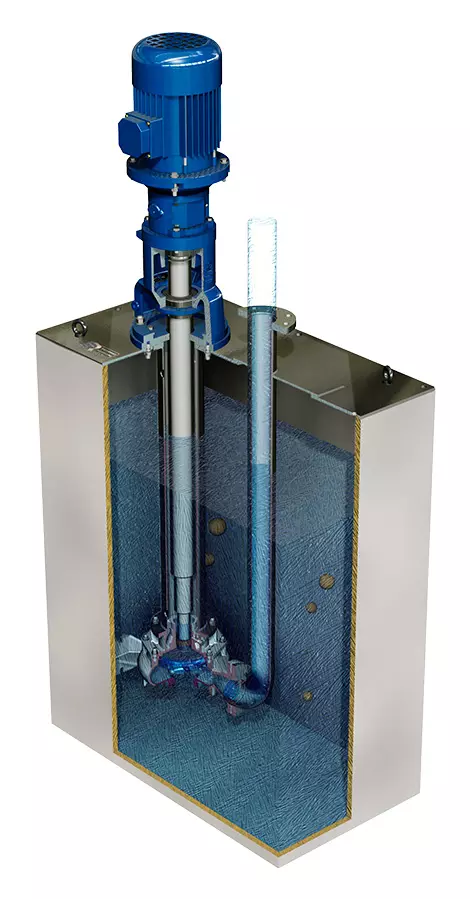

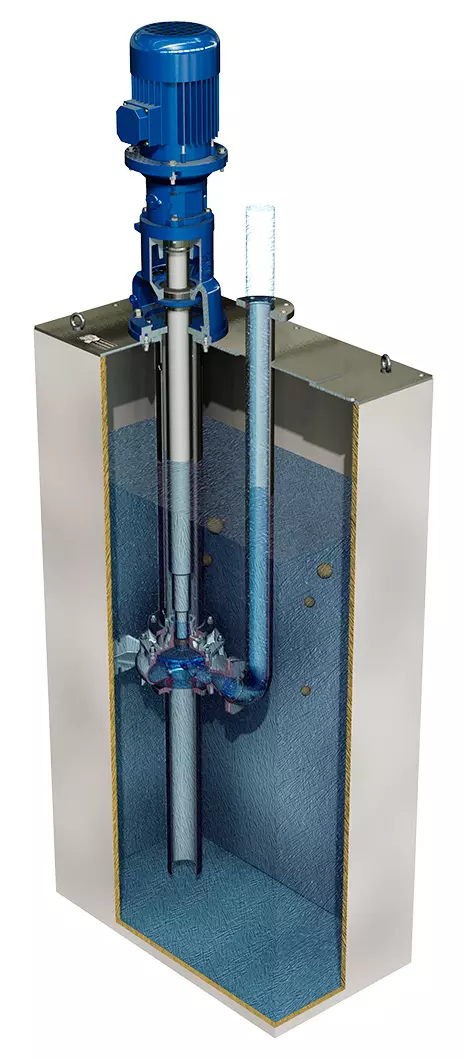

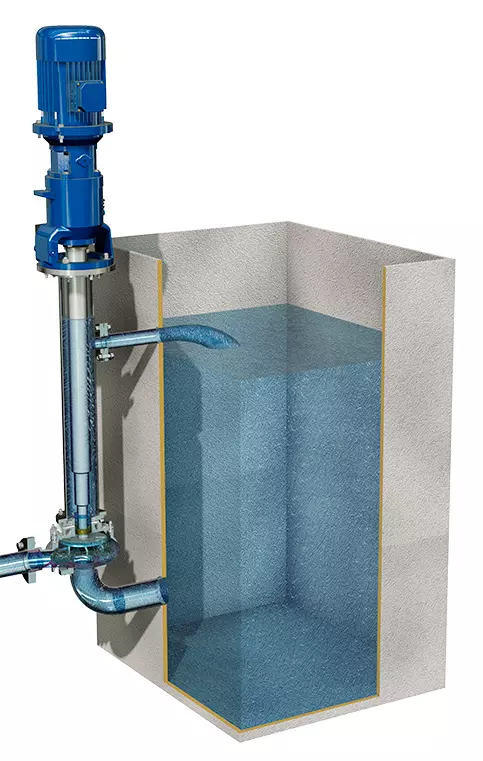

Vertical cantilever sump pumps with non-clogging vortex and channel impeller.

The pump body is immersed into the liquid,whilst the motor is mounted above the plate, keeping it away from the liquid.

Oversize heavy duty ball bearing are supplied with grease fittings and located above the mounting plate out of the corrosive area.

This means:

- None of the bearings are in the liquid and there is no shaft seal or bearing bush;

- Bearing assembly is sealed-off to prevent bearing contamination by liquids or gases-vapors;

- Pumps can run dry without risk of damage;

- Reliable operation and reduced cost.

The possibility to customize mounting plate shape and dimensions, discharge flange position and column length, allows designers and end-users to match sump or tank plates or flanges.

FIELDS OF APPLICATION:

Used for sludges, slurries and liquids containing large or long solids.

Typical applications include:

drainage sumps, oily water sumps, tank transfer, food processing, ground water development and irrigation, heavy oil, oil sands and shale, paper stock, sewage collection and treatment, shower pumps, slurry processing, slurry transfer.